UK railways marked a technological leap as Hitachi Rail‘s intercity battery train completed trials in northern England, achieving fuel savings of 35-50% – surpassing initial 30% projections. The 700kW battery system powered trains to speeds over 75mph (120 km/h) while maintaining scheduled journey times.

The battery unit, matching a diesel engine’s weight and fitting in the same undercarriage space, powered the train for 70 km on battery mode alone. This range proved sufficient for bridges, tunnels, and station approaches – a practical solution for non-electrified sections of track.

TPE’s Nova 1 trains, retrofitted with the battery system, demonstrated reliable performance across complex routes between York-Manchester Airport and Leeds-Liverpool Lime Street. The battery seamlessly switched between power sources, maintaining consistent speed and schedule adherence.

“Rail is already the most environmentally friendly form of public transport,” stated Rail Minister Lord Hendy. “This technology will play a vital role as we deliver our ambitious plans to transform and decarbonize the railways, and it could open the door to a more affordable expansion of the network for communities across the country.”

The £17 million project taps into Britain’s domestic battery supply chain, with partnerships including Sunderland-based Turntide Technologies. This localization strategy aligns with similar initiatives worldwide – Deutsche Bahn in Germany operates battery trains on regional routes, while SNCF in France tests battery-electric multiple units for branch lines.

Technical comparisons with alternatives show distinct advantages. While hydrogen trains like Alstom’s Coradia iLint offer longer ranges (1,000km), battery systems prove more energy-efficient for shorter routes, with simpler infrastructure requirements. The Masaccio battery-hybrid train in Italy has reduced CO2 emissions by 50% compared to diesel predecessors.

Jim Brewin, Chief Director of UK & Ireland at Hitachi Rail, emphasized the trial’s reliability: “Everyone should be immensely proud of creating battery technology that had zero failures during the entire trial. Using our global expertise, Hitachi Rail has created new technology which means the greenest mode of transport, just got greener.”

Similar Posts

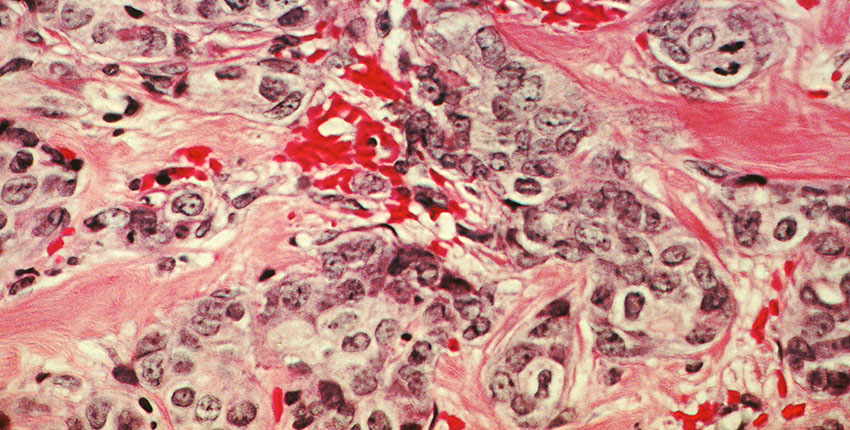

Mastering the complexities of battery degradation is essential for the cost-effective decarbonisation of energy grids and transportation. Despite its challenging reputation, understanding battery degradation is crucial for extending operational lifetimes. According to researchers, predicting battery end-of-life (EoL) with accuracy is vital to mitigate the risks of thermal runaway, ensuring safer and more reliable systems.

North East Mayor Kim McGuinness connected past and future: “We are the region that brought coal-powered engines to the world; now we’re delivering clean trains, which will help us build the greenest public transport in the country and deliver our transition to net zero.”

The trial’s success positions Hitachi Rail to develop full intercity battery-electric trains with 100-150 km ranges. This capability could eliminate electrification infrastructure needs in tunnels and stations, potentially saving hundreds of millions in construction costs.

Angel Trains CEO Malcolm Brown highlighted broader implications: “This multimillion-pound investment has shown the benefits that battery technology can deliver on existing and new fleets, driving forward a greener mode of transport that benefits passengers and the environment.”

Recent railway electrification projects in Britain average £2.5m per track-kilometer. Battery trains could reduce these costs by enabling partial electrification strategies, particularly useful for complex urban sections or historic structures where overhead wires prove challenging.

Passenger experience improvements include reduced noise at stations and smoother acceleration compared to diesel. The trial demonstrated air quality benefits, with zero local emissions during battery operation – particularly valuable for enclosed station environments.

Hitachi collaborates with the University of Birmingham on next-generation battery technology. Similar research partnerships worldwide, including JR East’s projects in Japan and China’s CRRC developments, suggest accelerating progress in railway battery technology.

The successful trial represents practical progress toward UK rail decarbonization targets. With thousands of diesel trains operating globally, battery technology offers a pragmatic pathway to cleaner rail transport while working within existing infrastructure constraints.