Innovation is the essence of the 21st century. The world of cars and that too EVs is not an exception. The students of TU, Eindhoven, have made a new EV called Phoenix. Phoenix is the newest and highly sustainable electric car. Developed by TU/ecomotive, the students hope to inspire car manufacturers, as new legislation from Brusselsis on the way.

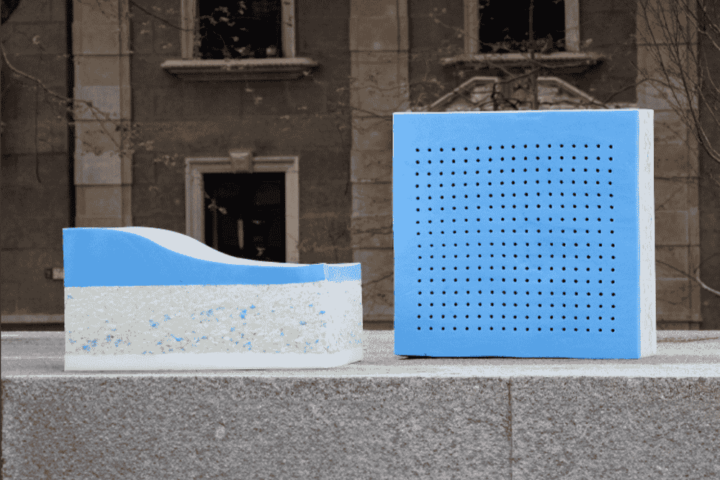

The Phoenix car can be reused for upto 75% in the next generation of vehicles. It is made by using mono-material structures (structures made from a single type of materials). The existing cars in Europe have a much lower so-called closed-loop recycling rate of only 21%. The design is a brand new one. These are the days of recycling.

Closed-loop recycling means that a material can be endlessly reused without significant loss of quality or certain properties. This is different from downcycling. Downcycling is a common reuse process in the automotive industry. In the car manufacturing area, recycled materials are repurposed into products of lower quality or reduced functionality.

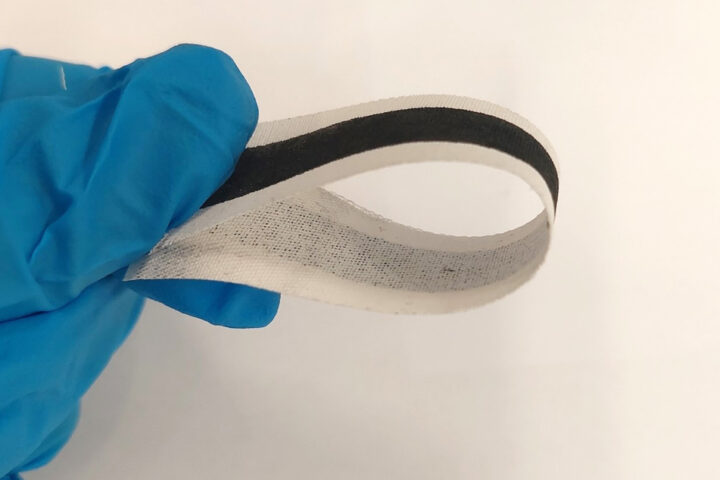

The Phoenix car uses smart assembly methods. In addition, batteries are generally challenging to reuse. Therefore, optimizing the lifespan of batteries is crucial. The TU/e team has achieved this by integrating both fixed and removable batteries into the car. Owing to the Smart design of Phoenix, the team has succeeded in setting a new standard for a circular economy.

Similar Posts

TU/exomotive is also responding to changing regulations from Brussels. It states that vehicles must consist of a set percentage of 25% recycled plastic. 25% of this must be closed-loop recycled from cars. The students see the new EUropean Commission guidelines as a step in the right direction.

Tim van Grinsven, team manager of TU/e, explains “The EC (European Commission) is heading in the right direction, but more is needed to truly transform the industry”. Van Grinsven Elaborates that the team’s goal is to inspire the automotive industry to design more sustainably. He says, “The earth does not provide unlimited resources, so using materials more efficiently is the solution. Phoenix is our answer to that challenge, and we invite the industry to join us in tackling it together.”

In short, TU/e students have developed a sustainable electric car from which four times more materials can be reused in new cars. With a smart design and closed-loop recycling, the PhoenixEV meets the EC regulations issued from Brussels. The TU/e team thus helps the circular economy. Phoenix optimizes battery life span. The team manager of TU/e Tim van Grinseven has invited the automotive industry to join them in tackling the use of limited materials problem.