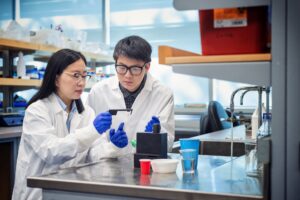

In a groundbreaking study published in the journal Current Opinion in Biotechnology in October 2024, researchers from Aalborg University in Denmark have made significant strides in transforming waste from wastewater treatment plants into valuable biopolymers. The REThiNk project, led by Professor Per Halkjær Nielsen from the Department of Chemistry and Bioscience, aims to revolutionize the way we perceive and utilize biomass from these facilities.

Harnessing the Power of Bacteria

Wastewater treatment plants are home to hundreds of different bacterial species that produce a wide range of biopolymers with unique properties. These biopolymers serve as an adhesive for the bacteria, allowing them to form colonies and adhere to surfaces, preventing them from being flushed out of the treatment plant. By altering the pH and temperature of the water, researchers can extract these biopolymers, which include cellulose and gelatinous substances, for various industrial applications.

Professor Nielsen explains, “In short, the work on biopolymers is about producing a lot of biomass in wastewater treatment plants that is actually bacteria that eat everything that enters the treatment plant so that only the pure water remains.” Depending on the size of the treatment plant, many tons of biomass are produced daily, which is typically converted into energy through biogas reactors. However, a significant portion of this biomass consists of biopolymers, which are in high demand as a sustainable alternative to oil-based polymers.

Sustainable Alternatives to Petroleum-Based Products

Currently, the petrochemical industry relies heavily on crude oil to manufacture synthetic polymers used in plastics, textile fibers, adhesives, and paints. However, the production of biopolymers from wastewater treatment plants offers a sustainable and eco-friendly alternative. These biopolymers can replace petroleum-based products in various applications, such as binding agents in paper and construction materials, and as a substance for flocculation in water purification processes.

Professor Nielsen emphasizes the potential impact of this development, stating, “The perspective is enormous, because you’re taking something that is currently waste and making high-value products from it.” With the ability to extract 20-30% of the biomass and convert it into biopolymers, this technology not only reduces waste but also provides a viable substitute for oil-based products.

Fire-Retardant Properties and Market Potential

One of the most promising aspects of biopolymers derived from wastewater treatment plants is their fire-retardant properties. This characteristic opens up a wide range of potential applications and increases their market value. If these biopolymers can be produced economically and sustainably on a large scale, there is a significant market opportunity waiting to be tapped.

Similar Posts

Extracting Valuable Minerals

In addition to biopolymers, the REThiNk project also focuses on extracting valuable minerals and components from the wastewater that enters treatment facilities. One such mineral is phosphorus, which is on the EU’s list of critical raw materials due to its potential scarcity in the future. By harvesting phosphorus and other minerals from wastewater, the project aims to maximize the value extracted from this often-overlooked resource.

Scaling Up for Industrial Production

The ultimate goal of the REThiNk project is to lay the groundwork for industrial-scale production of biopolymers from wastewater treatment plants. Professor Nielsen emphasizes the importance of building pilot-scale plants to demonstrate the feasibility of producing biopolymers in larger quantities. “There is great potential if companies can see that the product can be used for something and thus want to invest in testing and developing it. And this requires that we build pilot scale plants so that we can produce not just grams, but kilograms and in a few years’ time many tons,” he explains.

Mapping Bacterial Populations Worldwide

To fully realize the potential of biopolymer production from wastewater treatment plants, the REThiNk project also involves mapping the bacterial populations in these facilities worldwide. By understanding the specific roles and capabilities of different bacterial species, researchers can optimize the production process and tailor it to the unique characteristics of each treatment plant.

Environmental Benefits and Biodiversity Conservation

The production of biopolymers from wastewater treatment plants not only reduces waste and provides a sustainable alternative to oil-based products but also contributes to the conservation of biodiversity. Many biopolymers are currently derived from endangered kelp forests, putting these ecosystems at risk. By finding alternative sources for biopolymer production, such as wastewater treatment plants, we can alleviate the pressure on these fragile habitats and promote biodiversity conservation.

Professor Nielsen highlights this aspect, stating, “Today, many biopolymers are produced from seaweed from large kelp forests that are endangered. So if we can find other ways to extract biopolymers, it is a clear advantage for the environment and biodiversity as well.”

Collaborations and Future Outlook

The REThiNk project is a collaborative effort involving researchers from Aalborg University, Delft University in the Netherlands, and Aarhus University. By pooling their expertise and resources, these institutions aim to accelerate the development and implementation of biopolymer production from wastewater treatment plants.

As the world continues to seek sustainable and environmentally friendly solutions, the REThiNk project represents a significant step forward in the transition towards a circular economy. By transforming waste into valuable resources, such as biopolymers and minerals, we can reduce our dependence on fossil fuels, minimize waste, and protect our planet for future generations.

With the promising results already achieved and the potential for industrial-scale production, the future of biopolymers derived from wastewater treatment plants looks bright. As more companies recognize the value and sustainability of these products, we can expect to see a growing market for biopolymers in various industries, from construction and paper manufacturing to water purification and beyond.

The REThiNk project serves as a shining example of how innovative thinking, scientific expertise, and collaborative efforts can lead to groundbreaking solutions that benefit both the environment and the economy. As we continue to explore the untapped potential of wastewater treatment plants, we may uncover even more surprising and valuable resources that can contribute to a more sustainable future.